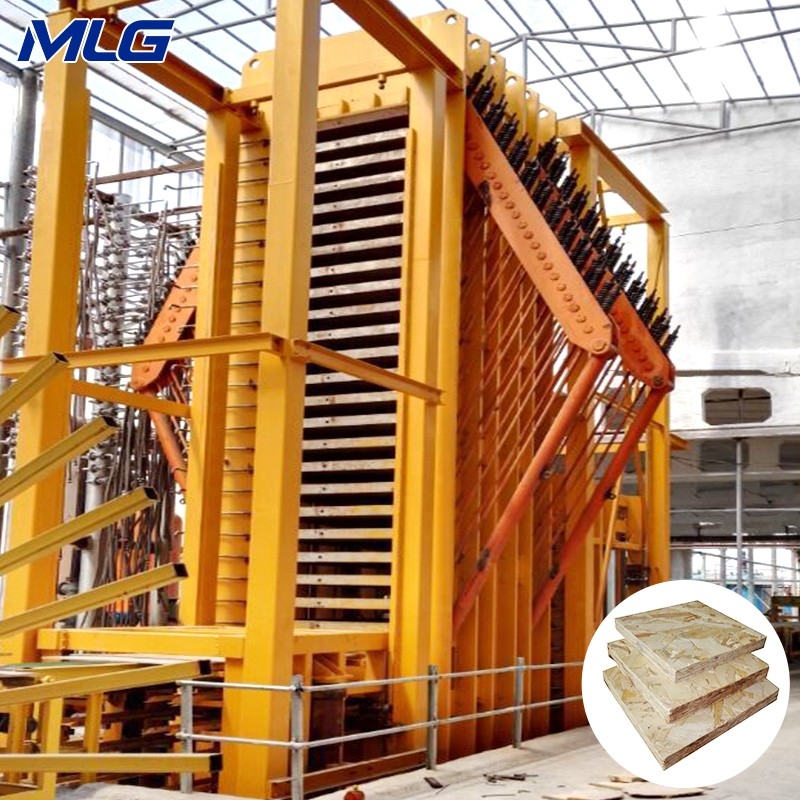

Veneer Composer Machine

|

List of Configuration for CGT-4BL Full Roller Gear Splicing Machine+4B1L Horizontal Splicing Machine+8-foot Plate Collecting Rack |

|||||

|

No. |

Application site |

Accessory Name |

Model |

Brand |

Number |

|

1 |

Horizontal splicing machine main body |

Main Frame |

Channel steel+steel plate |

Changxing Special |

1 |

|

2 |

Collecting frame body |

body frame |

Channel steel+steel plate |

Changxing Special |

1 |

|

3 |

Edge alignment drive device (horizontal assembly) |

Electromagnetic brake adjuster |

LSD-Z-10 |

Liso |

1 |

|

electrical machinery |

YE2-100L1-4 2.2kW |

Shandong Liju |

1 |

||

|

4 |

Front drive device (horizontal assembly) |

planetary reducer |

Ps142L1-008-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-180CS15B2-43P0 |

Xinjie |

1 |

||

|

5 |

Finished cutting blade driving device (horizontal splicing) |

Electromagnetic brake adjuster |

LSD-Z-10 |

Liso |

1 |

|

6 |

Rear drive device (horizontal assembly) |

planetary reducer |

Ps142L1-008-P2-S2 |

NEWSTART |

2 |

|

servo motor |

MS6H-180CS15B2-43P0 |

Xinjie |

2 |

||

|

7 |

Dragging feed (toothed joint machine) |

planetary reducer |

PF115L1-4-P2-S2/22-58-110-145-M8 |

NEWSTART |

1 |

|

servo motor |

MS6H-130CS15B2-42P3 2.3KW |

Xinjie |

1 |

||

|

8 |

Roller reversing (toothed joint machine) |

planetary reducer |

PS115L1-8-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-130CS15B2-42P3 2.3KW |

Xinjie |

1 |

||

|

9 |

Tooth cutting pre conveying (tooth splicing machine) |

planetary reducer |

PS115L1-8-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-130CS15B2-42P3 2.3KW |

Xinjie |

1 |

||

|

10 |

Tooth cutting drive |

Helical gear reducer |

R77-9.64-AM132-M1 |

Shanghai Shuangzhao |

1 |

|

three phase asynchronous Motor |

Y4-7.5KW-B5 |

1 |

|||

|

11 |

Middle warehouse conveying (toothed joint machine) |

planetary reducer |

PS142L1-8-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-180CS15B2-43P0 3KW |

Xinjie |

1 |

||

|

12 |

Rear transmission (tooth splicing machine) |

planetary reducer |

PS142L1-8-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-180CS15B2-43P0 3KW |

Xinjie |

1 |

||

|

13 |

Rear cutter drive (toothed joint machine) |

planetary reducer |

PF142L2-12-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-180CS15B2-43P0 3KW |

Xinjie |

1 |

||

|

14 |

Drive device for collecting plate frame over bridge |

Cycloidal pin wheel reducer |

BWDO-9-0.75 0.75KW |

Changzhou Dongli |

1 |

|

15 |

Drive device for the lifting shaft of the pallet rack |

electrical machinery |

YEJ-100L1-4 2.2kW |

Shandong Liju |

1 |

|

Reduction gearbox |

WPDS100-60-B 2.2KW |

Hangzhou Boyu |

1 |

||

|

16 |

Wooden veneer drive device for receiving frame |

electrical machinery |

YE3-90L-6 1.1KW |

Shanghai Anli |

1 |

|

17 |

Discharge device |

Cycloidal pin wheel reducer |

BWY1-59-1.5 |

Changzhou Dongli |

1 |

|

Configuration List of Full Roller Gear Splicing Machine (CGT-4BL) |

|||||

|

No. |

Application site |

Accessory Name |

Model |

Brand |

Number |

|

1 |

Host body |

Main Frame |

Channel steel+steel plate |

Changxing Special |

1 |

|

2 |

Dragging feed |

planetary reducer |

PF115L1-4-P2-S2/22-58-110-145-M8 |

NEWSTART |

1 |

|

servo motor |

MS6H-130CS15B2-42P3 2.3KW |

Xinjie |

1 |

||

|

3 |

Drum reversing |

planetary reducer |

PS115L1-8-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-130CS15B2-42P3 2.3KW |

Xinjie |

1 |

||

|

4 |

Middle warehouse conveying |

planetary reducer |

PS142L1-8-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-180CS15B2-43P0 3KW |

Xinjie |

1 |

||

|

5 |

The After Years |

planetary reducer |

PS142L1-8-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-180CS15B2-43P0 3KW |

Xinjie |

1 |

||

|

6 |

Tooth cutter |

Helical gear reducer |

R77-9.64-AM132-M1 |

Shanghai Shuangzhao |

1 |

|

three phase asynchronous Motor |

Y4-7.5KW-B5 |

1 |

|||

|

7 |

Rear blade drive |

planetary reducer |

PF142L2-12-P2-S2 |

NEWSTART |

1 |

|

servo motor |

MS6H-180CS15B2-43P0 3KW |

Xinjie |

1 |

||

|

8 |

electrical control system |

PLC computer control |

H3u series |

Huichuan/Other |

1 |

|

Display (human-machine) |

TPC1021Nt |

Kunlun Tongtai/Other |

1 |

||

|

circuit-breaker |

NXB series |

chint |

|||

|

Contactor |

NXC series |

chint |

|||

|

Intermediate relay |

MY2N-GS |

Omron |

|||

|

Parameters of CGT-4BL full roller toothed joint machine+4B1L horizontal splicing machine+8-foot plate collecting frame |

|||

|

External dimensions (conventional receiving frame) |

11.5m*13m*3.5m |

||

|

total power |

Tooth splicing machine 30KW+horizontal splicing machine/plate collecting frame 32.1KW=62.1KW |

effect |

Continuous mode 4.5 sheets/min, docking mode 5.5 sheets/min |

|

Cooling system |

2P |

Plate thickness |

1.7--3mm |

|

Plate size (conventional) |

4 feet/(3 feet optional) |

Board size (conventional) |

4 feet * 8 feet (optional 3 feet * 6 feet) |

|

Gas consumption (0.6~0.8MPa)) |

1380L/min |

||

Note: If the specifications, models or brands of accessories change due to product changes or upgrades, no further notice will be given!

You Might Also Like