Electric Heating Boiler

|

Place of Origin |

Shandong, China |

|

Condition |

New |

|

Type |

Boiler |

|

Weight (kG) |

150 kg |

|

Applicable Industries |

Building Material Shops, Machinery Repair Shops Manufacturing Plant, Construction works , Energy & Mining, Other, wood-baes,wood-based panel factory, woodworking machinery |

|

Warranty |

1 Year |

|

Key Selling Points |

Energy saving |

|

Usage |

Plywood Production |

|

Brand Name |

MLG |

|

Voltage |

380V |

|

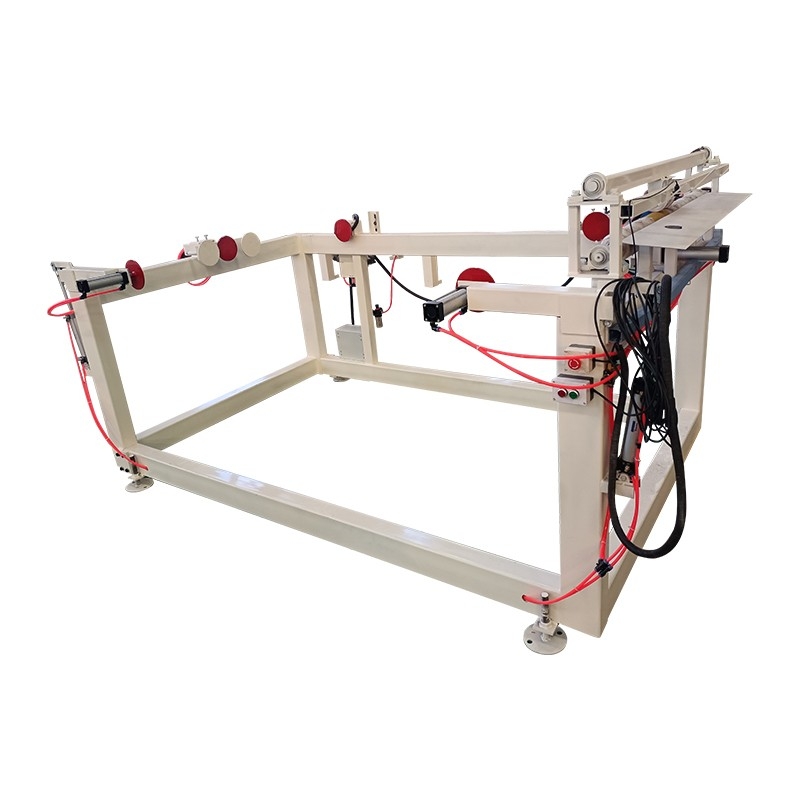

Dimension(L*W*H) |

1400x550x1200 |

|

Power (kw) |

24/36 |

|

Video outgoing-inspection |

Provided |

|

Warranty of core components |

1 Year |

|

Core Components |

Bearing, Motor, Pump, Gear, PLC, Gearbox, Pressure vessel, Engine, Other |

|

Parameter |

HEOT-40 |

|

Heat transfer media |

Heat conducting oil |

|

Cooling |

INDIRECT COOLING |

|

Maximum pump flow |

200 |

|

Maximum pump pressure |

3 |

|

After-sales Service Provided |

provided |

|

Cooling water pipe |

3/8x4 |

|

Oil reserves |

55 |

|

Temperature accuracy |

PID+1℃ |

|

Temperature range |

300℃ |

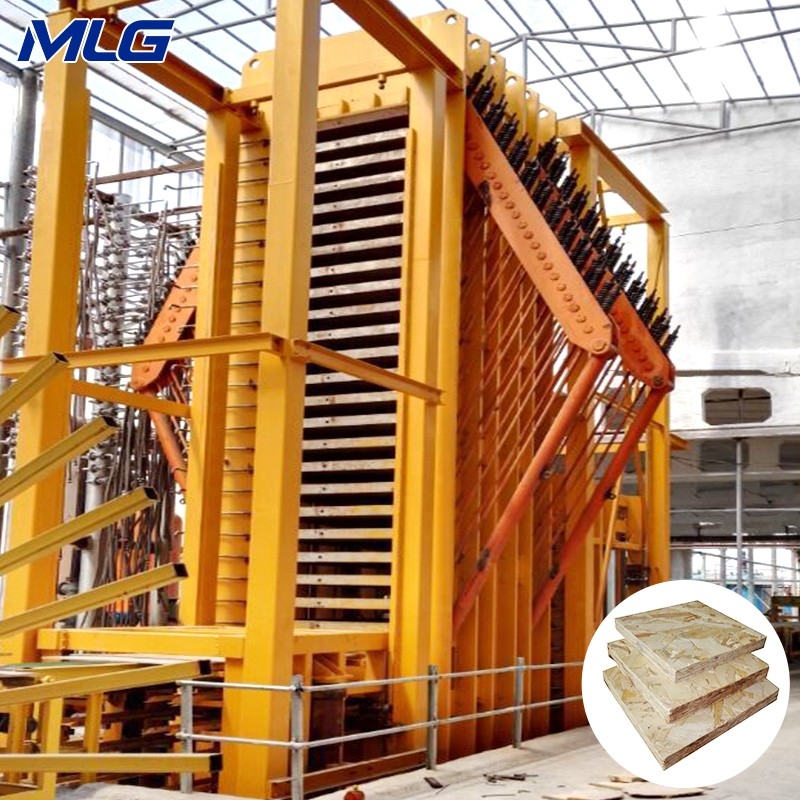

Product Overview

Boiler for plywood hot press machine

Boiler is equipmented with the whole plywood production line, particle board production line and the osb production line.

Feature:

1. High temperature in a low pressure

2. Stable heat system

3. Easily temperature control.

4. High heat efficient

5. Excellent operation control system

6. Safe monitor device

7. Less water, electricity, production cost

Technique data:

Rated thermal power is 0.12Mw (10×104kcal/h) to 14Mw (1200×104kcal/h).

Design pressure is equal to or greater than 1 Mpa.

Operating temperature is equal to or less than 350°C.

Thermal efficiency is between 60% and 85% according to the difference of boiler type.

Fuel:

Coal, water gas, city gas, mixed gas, light oil, heavy oil, residual oil, mixed oil, coal dust,coal water slurry, saw dust, bagasse, straw, waste oil and waste liquid.

Burning system

Coal-fired:

Fixed grate combustion, hydraulic jacking system, spiral jacking system, reciprocal

grate system, travelling grate system.

Oil-fired:

Mechanical atomization system, rotary cup atomization system, set cup atomization

system, steam atomization system, air atomization system.

Gas-fired:

Fuel gas filter, pressure switch, Gas pressure regulator, leak detection pump,solenoid valve

You Might Also Like